Urea-Formaldehyde (UF) resin is a thermosetting adhesive widely used in the production of wood-based composite materials such as particleboard, medium-density fiberboard (MDF), and plywood. UF resin has specific properties that make it suitable for various applications. Here are some key properties of UF resin:

- Adhesive Nature:

- UF resin is a thermosetting adhesive, meaning it undergoes a chemical reaction during curing to form a permanent and rigid bond.

- Curing Time:

- UF resin generally has a longer curing time compared to some other resin types. This longer curing time can be advantageous in certain manufacturing processes.

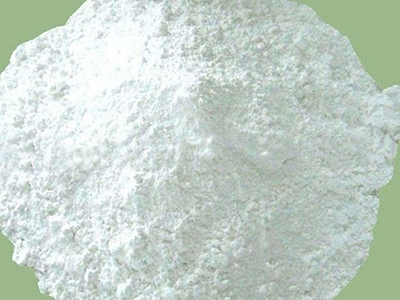

- Color:

- UF resin is typically light in color, often appearing yellow or cream-colored. The light color can be beneficial in applications where the appearance of the final product is a consideration.

- Cost-Effectiveness:

- UF resin is generally more cost-effective than some other resin types, making it a popular choice for the production of wood-based composite materials.

- Adhesion to Wood Fiber:

- UF resin exhibits good adhesion to wood fibers, contributing to strong bonds in composite materials.

- Water Resistance:

- While UF resin provides moderate water resistance, it is not as water-resistant as some other resins, such as Phenol-Formaldehyde (PF) resin. As a result, UF resin is typically used in interior-grade applications.

- Durability:

- UF resin provides satisfactory durability for many interior applications. It is commonly used in the manufacture of particleboard, MDF, and interior-grade plywood.

- Formaldehyde Emission:

- One challenge associated with UF resin is the potential for formaldehyde emissions. UF resins may emit formaldehyde, and efforts have been made to develop low-emission or no-added-formaldehyde (NAF) formulations to address environmental and health concerns.

- Applications:

- UF resin is extensively used in the production of interior-grade wood composite products, including particleboard, MDF, and some types of plywood. It is suitable for applications where high water resistance is not a primary requirement.

- Processing Temperature:

- UF resin typically requires elevated temperatures for curing. The specific curing conditions depend on the formulation and application.

It’s important to note that advancements in resin technology have led to the development of modified UF resins with improved properties, including reduced formaldehyde emissions. Additionally, the choice of resin depends on the specific requirements of the end product, such as the intended application, desired performance characteristics, and environmental considerations. Always refer to the manufacturer’s specifications and industry guidelines when working with UF resin or any other adhesive material.