PF resin (Phenol-Formaldehyde resin) and UF resin (Urea-Formaldehyde resin) are both types of thermosetting resins commonly used as adhesives in the manufacturing of wood-based composite materials. While they share similarities, there are distinct differences between PF and UF resins:

- Composition:

- PF Resin: Phenol-Formaldehyde resin is made by reacting phenol with formaldehyde in the presence of a catalyst. Phenol is a derivative of benzene, and the reaction results in a three-dimensional cross-linked structure.

- UF Resin: Urea-Formaldehyde resin is produced by reacting urea with formaldehyde. This reaction also forms a cross-linked structure, but the composition and properties differ from PF resin.

- Color:

- PF Resin: Phenol-Formaldehyde resin tends to be darker in color, often having a reddish-brown hue.

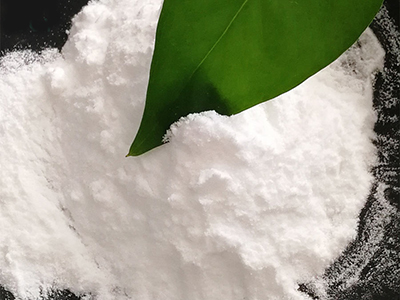

- UF Resin: Urea-Formaldehyde resin is typically lighter in color, often appearing more yellow or cream-colored.

- Curing Time:

- PF Resin: PF resins generally have a shorter curing time compared to UF resins. They set quickly and contribute to a faster production process.

- UF Resin: Urea-Formaldehyde resins generally have a longer curing time. This longer curing time can be an advantage in certain applications.

- Cost:

- PF Resin: Phenol-Formaldehyde resin is often more expensive than UF resin. The cost difference is influenced by factors such as raw material prices and production processes.

- Performance:

- PF Resin: PF resins offer high water resistance, chemical resistance, and excellent heat resistance. They are commonly used in exterior applications and in situations where durability is critical.

- UF Resin: Urea-Formaldehyde resins also provide good water resistance but may not be as durable as PF resins in some demanding applications. UF resins are often used in interior applications.

- Applications:

- PF Resin: Phenol-Formaldehyde resins are commonly used in the production of exterior-grade plywood, marine plywood, and other applications where a high level of durability and resistance to environmental factors is required.

- UF Resin: Urea-Formaldehyde resins find applications in interior-grade plywood, particleboard, and medium-density fiberboard (MDF). They are suitable for applications where water resistance and durability are not as critical.

It’s important to note that both PF and UF resins are formaldehyde-based adhesives, and formaldehyde emissions can be a consideration, especially in indoor applications. However, advancements in resin technology have led to the development of low-emission and no-added-formaldehyde (NAF) formulations to address environmental and health concerns. Always refer to specific product specifications and adhere to safety and environmental guidelines when working with these resins.