The edge sealing of furniture is very important, and what glue is used when the wood edge is edged?

1. What glue is used for edge sealing

1. When sealing the edge of the wood board, use a special Edge banding adhesive. For example, you can choose EVA hot melt adhesive. This is divided into two types, one is filler, the other is no filler, which can be used as ordinary furniture edge sealing . However, it has a defect, that is, the heat resistance performance will be slightly worse, and the temperature should not exceed 120 degrees.

2. You can also choose polyamide hot melt adhesive, its heat resistance is slightly better, and the solidification speed is still very fast. However, there is also a drawback, the price is slightly more expensive. Considering the price/performance ratio.

3. Polyurethane hot-melt adhesive can also be selected, its performance is very ideal, and it can ensure high-quality edge sealing requirements.

Second, the performance requirements of furniture edge sealing glue

1. It can be used as an edge sealing glue for furniture wood. When choosing, we must consider its viscosity. Of course, it does not directly reflect its performance. However, the higher the viscosity, the better its performance will be. And try to choose a faster setting speed, which can improve its initial setting strength.

2. When choosing, also consider its density. The normal density range should be 1.0~1.6 grams per cubic centimeter. And its density depends on the amount of filler and the composition.

3. When choosing, pay attention to its softening point. If the value is larger, the glue will not melt easily. At the same time, it should be combined with the temperature used, including its water resistance and environmental protection performance. If it is better, relatively speaking, it can be adopted by the market.

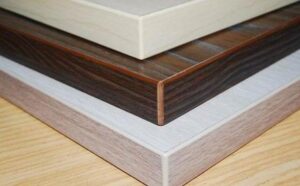

3. The role of sheet edge sealing

Edge banding should be an important process in furniture production, that is to say, it needs to be pasted on the edge or corner through edge banding. Its function can improve the integrity, avoid moisture and mold on both sides, and can play a better decorative effect.

And because the edge is sealed, the release of harmful gases can be suppressed, so as to achieve the effect of beauty, reinforcement and environmental protection.